When it comes to packaging a product, looks can attract customers and differentiate the product on increasingly crowded shelves. Thermal transfer label rolls are a flexible use for high-quality labels that have crisp output of images and text with clear product information in your barcode system or retail environment. These are labels that can suit the needs of all types of packaging be it food item, electronics equipment or cosmetic & medicinal product.

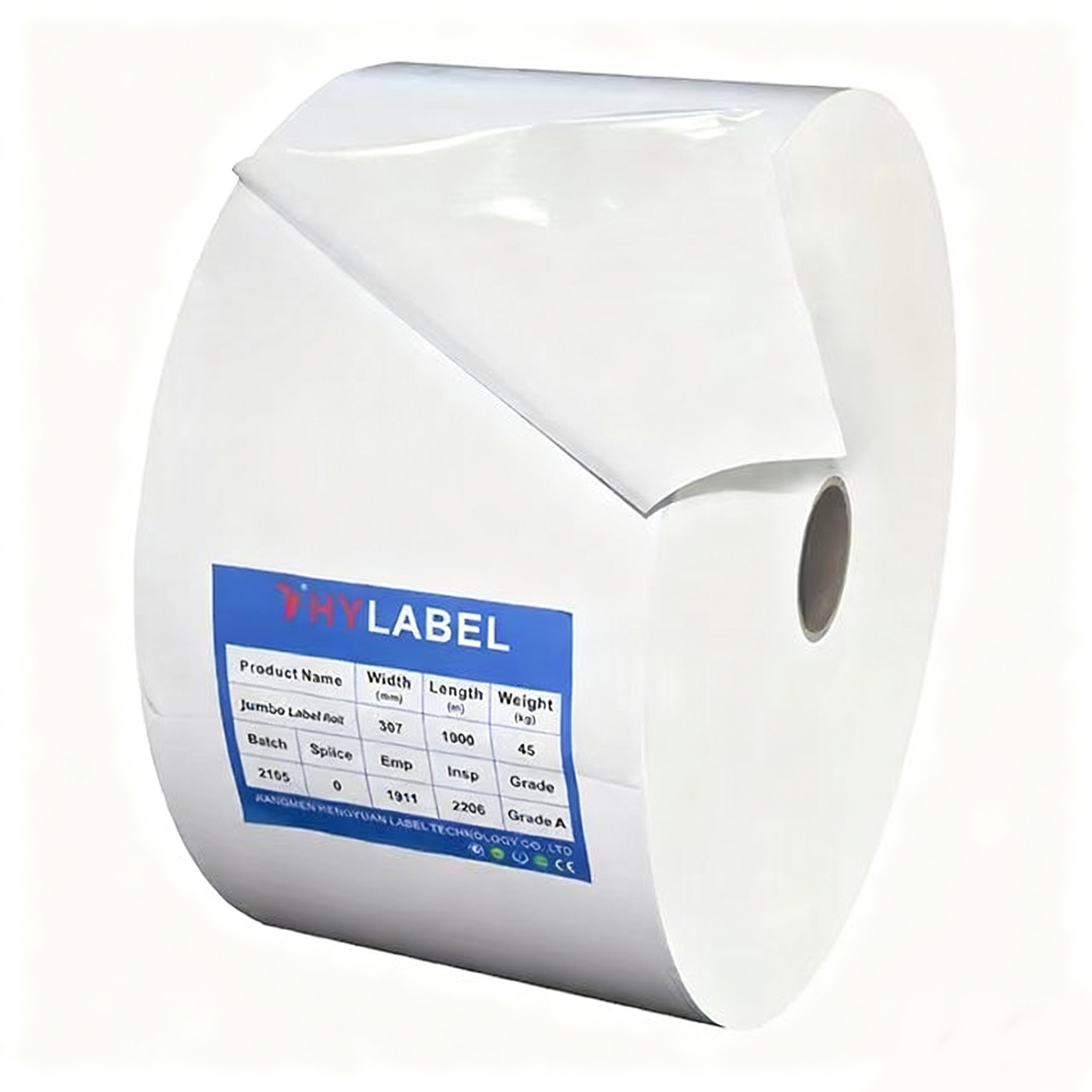

With HYLABEL thermal transfer label rolls, businesses can take the branding to a new level and coordinate packaging designs across multiple product alls. This thermal transfer label is also a durable option that will keep important information, such as barcodes, QR codes and expiration dates, intact throughout the life of your product. This works not as just a cosmetic to make things look good but also instills confidence amongst consumers by offering information they can trust.

Thermal transfer label rolls also looks more beautiful, and it is easy to print and use, which will increase the efficiency of work as well. Featuring printed variable data on-demand, businesses can easily respond to changes in market trends and promotion strategies since no pre-printed labels are required. This flexibility enables shorter lead time and more efficient package operation that result in better customer satisfaction and higher volume.

Good stock management is vital for smooth operations and to avoid customer dissatisfaction due to inadequate or delayed supply. There are innovative label solutions for both industrial, commercial and personal use to help keep your company organized and tracked. Thermal transfer label rolls simplify the inventory process with precise labeling at the touch of a button! These labels also feature a fade resistant quality that will prevent them from smearing, smudging or rubbing off to ensure long lasting storage.

With the help of thermal transfer label rolls from HYLABEL, companies will be able to establish a structured labeling process to finding products; locations (anywhere in their inventory) and quantities. This is a level of organization that makes the counting, restocking and order filling of stocks easier and with less mistakes helping keep your inventory accurate. Well labeled, items are easy to identify against the clear labeling on all items in your inventory and staff carrying out checks have no need to waste time trying to work out what each item is.

And thermal transfer label rolls allow for barcode printing, providing the technology that will give you a competitive advantage in automation, real-time inventory tracking and more. It allows for effective inventory management, restocking and ordering, reducing the risk of shortages or overstocks. Leveraging custom thermal transfer labels, they can increase visibility of their inventory in the warehouse or from distribution, drive operational efficiency and ultimately impact the bottom line by reducing cost while increasing productivity.

HYLABEL Thermal transfer label rolls are also used in many manufacturing environments for inventory control, product labeling, and shipping and receiving. The food and beverage industry relies on these labels for expiration dates, nutritional information and ingredient lists on packages. The logistics and transportation sector uses thermal transfer label rolls for tracking loads, packaging parcels, and organizing stock in the warehouse. In conclusion, industrial thermal transfer labels are instrumental in helping to keep many different industries running efficiently and organized.

With annual participation in international label exhibitions and a market reach spanning North America, Europe, Southeast Asia, the Middle East, and beyond, we possess proven expertise in serving a worldwide clientele with reliable export and logistics support.

Through strategic factory expansions, relocation to modern industrial zones, and the launch of advanced production lines like our silicone-coated water-based adhesive line, we consistently enhance our production capacity, product quality, and service capabilities to meet growing global demand.

We offer a comprehensive range of label materials, including Direct Thermal, PP, PET, PE, and Synthetic labels, catering to critical sectors such as food, medical, logistics, and retail, providing versatile solutions for various printing and application needs.

Building on over 20 years of experience since 2003, our journey from paper products to specializing in self-adhesive labels (since 2016) demonstrates deep-rooted manufacturing expertise and a successful, strategic evolution into a dedicated label technology leader.